The Hidden Downsides of “DIY” Mini-Split Installations

Mini-split systems are showing up everywhere, from garages and workshops to bonus rooms and small apartments. The rise of “DIY” mini-split kits from big-box stores and online retailers has made it easier than ever for homeowners to consider installing one themselves.

Saving on installation costs can be appealing, as is the pride you get from DIY projects, but there are several downsides of the DIY approach that can turn a simple HVAC project into an expensive headache.

What’s Actually Involved in a DIY Mini-Split Installation?

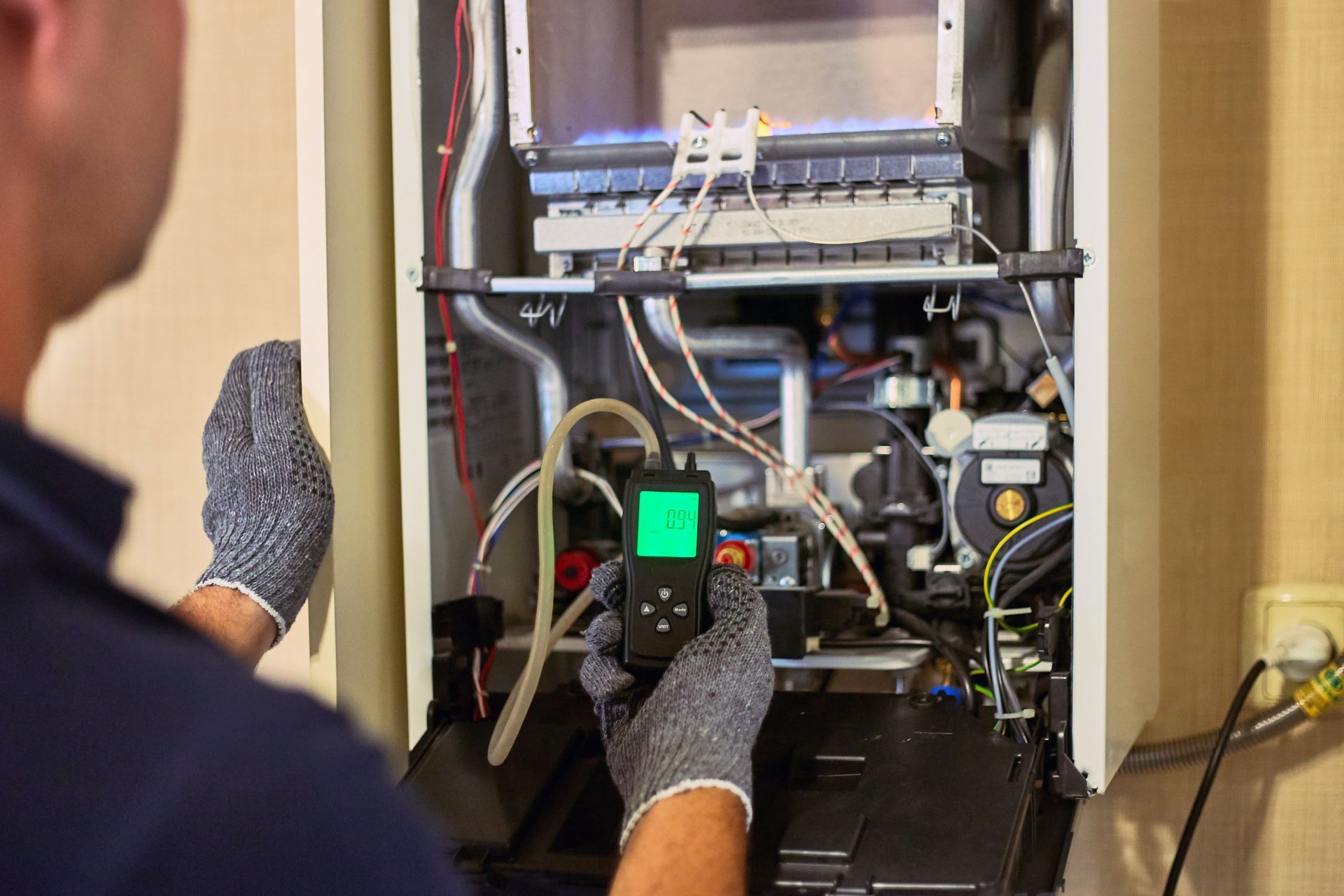

A typical DIY mini-split kit comes with a pre-charged line set, quick-connect fittings, mounting hardware and basic instructions. The appeal is obvious: in theory, you drill a hole, hang the air handler, connect the lines and you’re done.

The reality is more complicated. Getting the line set through brick, siding or tight attic spaces is physically demanding, and supporting the unit correctly takes more skill than many first-timers expect.

Warranty and Local Code Pitfalls

Most mini-split manufacturers restrict or void their warranty if the system isn’t installed by a licensed contractor. Even “DIY-friendly” models often have fine print that limits coverage for self-installed systems.

In the Dallas-Fort Worth area, code and permit requirements can vary significantly from one city to another. Some areas require a mechanical permit for any HVAC install, others focus on the electrical hookup or refrigerant handling. The safest approach is to work with a local HVAC contractor who knows the rules for your specific area.

Beyond local regulations, improper installation can raise issues with mortgage lenders or home insurance providers, especially if an unpermitted system causes damage or fails a future home inspection.

Where Most DIY Installs Go Wrong

- Line Set Routing: Running the refrigerant lines through exterior walls, crawlspaces or attics without kinks or damage is one of the most challenging parts of any mini-split install. Insufficient support or poor insulation can lead to leaks or performance loss.

- Electrical Hookup: Mini-splits require a dedicated circuit, disconnect box and safe wiring. Mistakes here are common and can cause nuisance trips, system shutdowns or even safety hazards.

- Vacuum and Charging: Even with pre-charged kits, it’s easy to introduce air or moisture into the system, leading to long-term damage. Missing or rushing this step can cut efficiency and mini-split lifespan.

Performance and Efficiency Pitfalls

A mini-split that isn’t properly installed may work, at least at first, but often underperforms. Well-intentioned homeowners can end up with:

- Poor heating or cooling in the target room

- Ongoing error codes or unexplained shutdowns

- Higher energy bills due to system inefficiency

- Increased wear and shorter equipment life

Troubleshooting these issues without the right tools or training is difficult, and many DIY installers eventually need a professional to finish the job or fix problems.

The True Cost of a DIY Mini-Split Installation

DIY projects, at least when they’re done well, take a homeowner longer than it would a professional. From needing to constantly go back to how-to YouTube videos to repeat return trips to the hardware store, speed bumps and complications are an inevitable part of the DIY process.

Most homeowners also lack the mini-split installation muscle memory of an HVAC technician, and their desire to get things right slows down their pace of progress.

Your time is valuable, and what you save in labor might not actually be that much when you consider how much longer it’ll take you to do the job than it would a professional.

Many homeowners also underestimate the cost of tools and materials. Even “DIY” kits often require additional items like mounting hardware, line set covers, electrical components or specialty tools.

Small installation mistakes, like improper line set support, poor drainage slope or loose electrical connections, can lead to performance problems that require professional repair later.

Long-term performance is another consideration. Mini-splits are sensitive systems, and even minor installation errors can reduce efficiency or shorten equipment life.

Why It’s Best to Call an HVAC Technician for Mini-Split Installation in Fort Worth and Arlington

Hiring a professional isn’t just about checking a box for code or warranty purposes. A licensed HVAC contractor will handle the line set, electrical and refrigerant charging correctly and safely, ensuring peak system performance and full manufacturer warranty.

When you work with Tom’s Mechanical for your mini-split installation, you also get the peace of mind that comes from knowing that in the unlikely event a mistake was made, our HVAC technicians will address the problem at no additional cost to you.

For expert mini-split installation or troubleshooting in North Texas, call Tom’s Mechanical at (817) 277‑4493.